SensaDyne Software for Windows®

Windows '95 through Windows 11 Operating Systems

for all SensaDyne Computer-Interfaced Tensiometers

Standard Program Features

· On-Screen Automatic Calibration (AutoCal) Buttons for Faster Surface Tension Calibrations with expanded choice, for low standard calibration fluid, of Ethyl, Isopropyl, or Methyl Alcohol. *

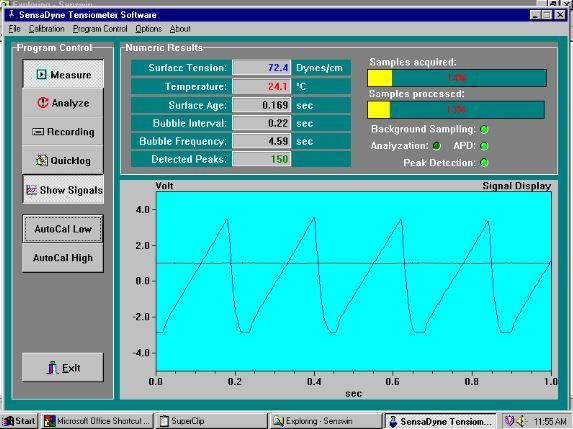

· Continuous Real Time Data Acquisition and Display for Surface Tension, Temperature, Surface Age, Bubble Interval, and Bubble Frequency, along with Maximum Bubble Pressure Waveform and Temperature Signals.

· Faster Test Results with User-Selected Options for Analyzation Time.

· Automatic Surface Age Measurement for Surfactant Diffusion Rate Studies.

· Expanded Capabilities for Viscous Fluids with Viscosity Compensation software features.

· Graphic User Interface for direct Graphing of Data on Linear or Logarithmic axis. All Data Files convertible to ASCII Format for importing to other graphing and spreadsheet programs.

· On-Screen Status Indicators for Analyzation, Advanced Peak Detection, and Detected Peaks.

· Easy Access to Help Text Files for On-Screen Tensiometer Operation Assistance.

Minimum Computer Requirements

Computer Processor: Intel Pentium or compatible 32 bit processor.

Memory: 8 MB used by the program, 16 MB for data acquisition, (32 MB recommended). Display: VGA with screen resolution set to 800x600 or higher.

Additional Program Features

True Windows[1] Point and Click Operation:

32 bit version for all Windows® Operating Systems. True point and click mouse operation with pull-down menus for fast program navigation, operation, data file generation, and graphic display.

Advanced Software Peak Detection:

Positive triggering only on maximum differential bubble pressure peaks. Eliminates false triggering on electrical and/or pneumatic noise, and from viscous fluid effects. Adjustable analyzation time for faster readings when dealing with long surface age (equilibrium/static) measurements.

Automatic Surface Age Determination:

Calculates (does not estimate) precise values of Surface Age (surfactant migration time), under all operating conditions, from milliseconds to several minutes for all SensaDyne Tensiometers.

Real Time Bubble Pressure Display:

Concurrent viewing of surface tension maximum differential bubble pressure waveform while surface tension is being measured in real time.

Individual Peak Data Recording Option for Viscosity Compensation:

Allows the instrument, using a special data file collection software option, to be set up and used for true viscosity compensated surface tension measurements, using standard QC and PC tensiometers, when occasional viscous fluids need to be measured.

Expanded Graphing Capabilities:

Graph and print results of Surface Tension, Temperature, Surface Age, Bubble Interval and Bubble Frequency directly, with ASCII conversion for all data files. Linear to logarithmic axis. Full compatibility with earlier SensaDyne Windows® software files.

Surface Tension versus Surfactant ConcentrationCurves:

Generate and plot surface tension versus surfactant concentration, both manually or automatically (using the STS dispenser accessory) to determine both equilibrium and dynamic Critical Micelle Concentration (CMC) curves.

One Button “AutoCal” Calibrations: *

On-screen high and low AutoCal buttons allow more direct and faster calibration when using D.I. Water and Ethyl, Isopropyl, or Methyl Alcohol calibration standards. All standard calibration tables are stored in memory and accessed for calibration based on the measured sample temperature.

On-Screen Help Menu & E-Mail Access:

On-screen help menu features allow access to set-up, operation, and calibration text help files in program memory. Direct e-mail messaging and web site access allows users to send technical or operational questions to Technical Service representatives at SensaDyne..

Comprehensive Data Acquisition:

User-programmed “scan” or “time” options for data collection (Data File), and on-demand (Quicklog File) data collection of Surface Tension, Temperature, Surface Age, Bubble Interval, and Bubble Frequency. * except QC3000 Tensiometers

Additional PC500-Series Automatic Tensiometer Features

Improved Mass Flow Controller Operation:

Improved Mass Flow Controller (MFC) operation by unloading (purging) the MFCs before each user-programmed DynaCal (Dynamic Calibration) run and DynaCurv (Dynamic Curve generation) run. This sets the MFCs at the same physical setting and assures that the characteristics of the MFCs and mass flow is the same for every calibration and test run, increasing stability and repeatability.

Single, Multiple, and Continuous DynaCurv Operation Options:

Choose single, multiple, or continuous DynaCurv (Dynamic Curve generation) options. The tensiometer can be programmed for single or multiple tests runs with user-programmed time delay between test runs. This allows multiple dynamic curves to be run on single test samples to determine dynamic surface tension changes that may occur over time for the tested sample. Each distinct DynaCurv test result is automatically stored in a separate data file.

Strip Chart Voltage Values Display Option:

Analog output channel maximum voltage values for both Surface Tension and Temperature can be displayed on the screen to verify instrument stability, and to determine bubble frequency limitations for tested fluids.

Easier MFC Online Checking Capabilities:

Easier verification of computer COM port operation with the MFC controller board. More positive COM port and controller communication.

Simplified Mass Flow Controller Software Editor:

The MFC Control Panel has an editor option to allow software settings of the MFCs to be changed, and more precisely matched, to actual physical MFC settings in the event of, and following, a computer COM port malfunction or power interruption. Users no longer have to physically reset the MFCs or “jog” the MFCs back to their required positions.

[1] Windows is a registered trademark of Microsoft Corporation

Copyright © 1981-2023 SensaDyne Instrument Div. All rights reserved.